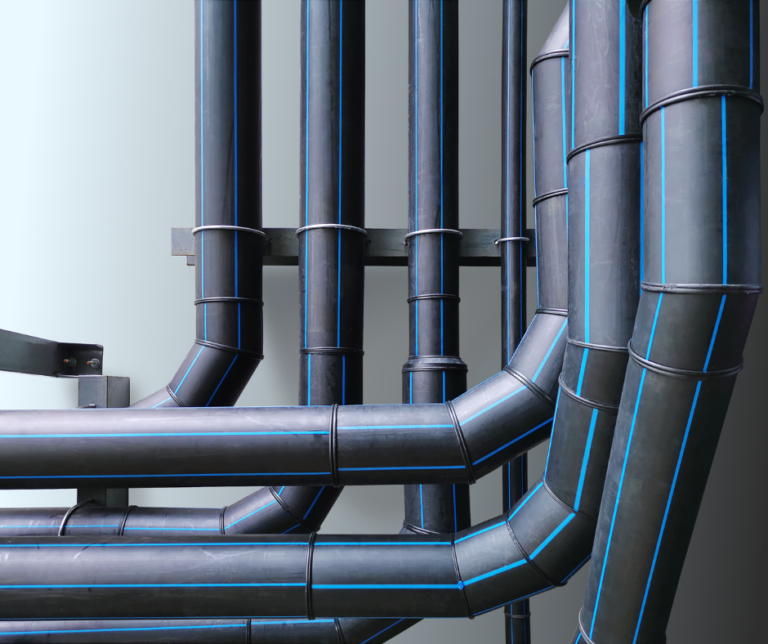

Comprehending the Key Benefits of HDPE Pipe for Water and Wastewater Monitoring

The use of HDPE pipeline in water and wastewater management offers countless benefits that warrant factor to consider. Its remarkable toughness and long lifespan make it a recommended selection for several projects. Additionally, the product's resistance to deterioration and chemical damages improves its integrity in different atmospheres. Nonetheless, the benefits extend past just longevity and resistance. Exploring its cost-effectiveness and environmental effect discloses a lot more engaging factors for its widespread adoption in modern-day facilities

Outstanding Sturdiness and Longevity

HDPE pipeline stands out for its extraordinary longevity and durability, making it a preferred option in water monitoring systems. Constructed from high-density polyethylene, these pipes can hold up against substantial pressure and stress, making certain trustworthy efficiency over time. Their durable nature enables them to sustain severe ecological problems, consisting of temperature changes and dirt motions, which can trigger various other products to fall short.

The life expectancy of HDPE pipes commonly goes beyond 50 years, offering an economical remedy for communities and industries alike. In addition, the material's lightweight buildings streamline setup, minimizing labor costs and timeframes. This sturdiness decreases the demand for regular repair work or replacements, additionally boosting its financial charm.

In water administration applications, the dependability of HDPE pipelines suggests fewer interruptions and boosted service continuity, making them indispensable to lasting facilities development. The mix of durability and long life solidifies HDPE's duty as a cornerstone in reliable water management solutions.

Resistance to Corrosion and Chemical Damages

While many products catch deterioration and chemical damage with time, HDPE pipes display impressive resistance, making them optimal for various water management applications. This resilience stems from the molecular framework of high-density polyethylene, which is naturally non-reactive and does not corrode like metals or weaken from direct exposure to severe chemicals. Because of this, HDPE is highly efficient in settings with aggressive substances, such as wastewater systems that may consist of acids, bases, and natural solvents.

In addition, HDPE pipes can endure environmental elements such as soil acidity and saline problems, further improving their viability for varied applications (custom hdpe pipe manufacturing Midland TX). Their ability to keep architectural honesty in time decreases the threat of leaks and failures, which is crucial in making sure the security and integrity of water distribution and wastewater monitoring systems. Subsequently, the resistance to corrosion and chemical damages significantly adds to the overall efficiency and long life of HDPE piping services

Cost-Effectiveness and Financial Advantages

When thinking about the economic implications of water administration systems, the cost-effectiveness of HDPE pipelines comes to be evident. These pipes use reduced installment and upkeep costs compared to traditional products like metal or concrete. Their lightweight nature streamlines transport and setup, leading to decreased labor expenditures. In addition, HDPE pipelines display a lengthy life-span, commonly surpassing half a century, which converts to less substitutes and long-term savings.

Additionally, the resistance of HDPE to corrosion and chemical damages reduces the need for costly fixings and replacements. The pipelines also support reliable water circulation, decreasing energy prices related to pumping systems. By alleviating leaks and water loss, HDPE pipelines add to substantial financial advantages for municipalities and markets alike. Generally, the first investment in HDPE piping can generate considerable economic returns over the life expectancy of the water monitoring system, making it a prudent selection for lasting facilities development.

Environmental Sustainability and Minimized Effect

Versatility and Flexibility in Installation

As a result of their unique buildings, HDPE pipelines provide impressive convenience and adaptability in setup, making them appropriate for a large range of applications. Their lightweight nature enables less complicated handling and transport, minimizing labor prices and installation time. HDPE pipelines can be bent and shaped to fit numerous surfaces and job requirements, which is particularly read more advantageous in challenging atmospheres.

In addition, their resistance to corrosion and chemical damage enables for setup in varied settings without the requirement for specialized protective layers. The capability to fuse joints creates a continuous, leak-free system, enhancing the overall integrity and integrity of the setup. HDPE's versatility additionally accommodates ground motion, decreasing the threat of damages in areas vulnerable to moving soil. Overall, these features make HDPE pipes not just functional yet also a favored selection for water and wastewater management systems.

Frequently Asked Questions

Just How Does HDPE Pipeline Compare to PVC in Water Administration Applications?

HDPE pipe uses superior versatility, resistance to corrosion, and resilience compared to PVC. Its lighter weight helps with simpler installment, while its lengthy life expectancy lowers substitute costs, making HDPE a preferred choice in water monitoring applications.

What Is the Lifespan of HDPE Piping Under Typical Problems?

Under regular conditions, HDPE pipes can have a life expectancy varying from 50 to 100 years. Their longevity and resistance to rust add to their long-term performance in numerous applications, making them a reliable option for facilities.

Are HDPE Pipeline Recyclable After Their Life Span?

Yes, HDPE pipes are recyclable after their life span. Midland TX HDPE Pipe Fittings in Stock. They can be processed and repurposed into new items, greatly decreasing ecological influence and advertising sustainability within the industry, making them an eco-friendly selection for piping services

What Is the Setup Process for HDPE Pipes?

The installment process for HDPE pipes involves website prep work, trenching, pipeline combination or mechanical joining, backfilling, and stress screening. Proper techniques assure a long lasting and efficient system for carrying water and wastewater successfully.

Can HDPE Pipeline Be Used for Both Drinkable and Non-Potable Water Equipments?

Yes, HDPE pipelines can be used for both drinkable and non-potable water supply. Their adaptability, longevity, and resistance to rust make them ideal for different applications, making certain safe and effective transport of water in different contexts.